Stainless steel workbench, laboratory instrument table, assembly line operation table, cafeteria table, stainless steel operation table, packaging table

Stainless steel workbench, laboratory instrument table, assembly line operation table, cafeteria table, stainless steel operation table, packaging table

1、 Core materials and processes

The quality core of stainless steel workbench depends on material selection and processing technology, and different configurations can adapt to the needs of different industrial environments:

-Main material: 304 stainless steel or 201 stainless steel is commonly used, and 316 stainless steel is selected for some high-precision scenarios. Among them, 304 stainless steel has a nickel content of ≥ 8%, strong corrosion resistance, and can resist workshop oil stains, weak acids and bases, and humid environments. It is the first choice for production workshops and warehouses; 201 stainless steel has a lower cost and slightly weaker corrosion resistance, making it suitable for ordinary warehouse scenarios that are dry and free from acid and alkali corrosion; 316 stainless steel with added molybdenum element has better corrosion resistance and is suitable for special production workshops containing chemical media and high humidity, such as electronic component production and food processing auxiliary areas.

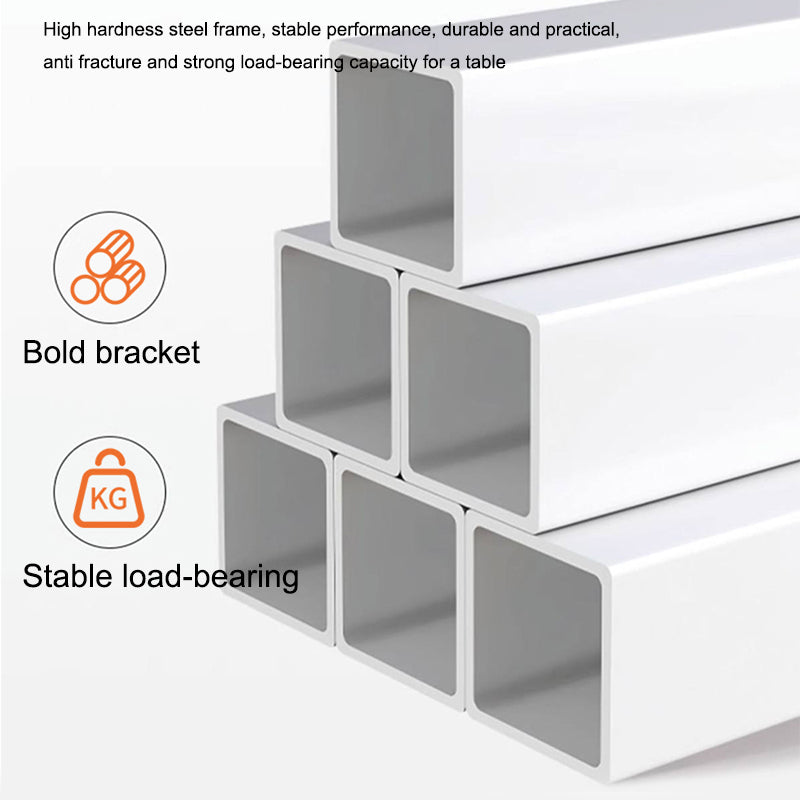

-Board specifications: The thickness of the countertop is usually 1.2-2.0mm, and the load-bearing countertop can be thickened to 3.0mm. The brackets are mostly made of Φ 38-50mm stainless steel round pipes or 20 × 40mm stainless steel square pipes, with a wall thickness of 1.0-1.5mm to ensure overall structural stability.

-Processing technology: The tabletop is made by cutting, bending, welding, polishing, and grinding, with a surface roughness of ≤ Ra0.8 μ m and smooth without burrs; The bracket adopts full welding process, and the welding points are polished without welding slag or protrusions; Some workbenches are equipped with reinforced crossbeams to further enhance their load-bearing performance; The bottom can be equipped with anti slip foot pads or universal casters to meet different placement needs.

2、 Core Features

1. Stable structure and strong load-bearing capacity: Adopting a frame style overall design, the bracket is closely attached to the tabletop. After load-bearing testing, the conventional workbench can uniformly bear 300-500kg, and the thickened and reinforced version can be increased to 800-1000kg. It can stably carry heavy materials, production equipment or semi-finished products, meeting the needs of warehouse goods storage and workshop heavy product assembly.

2. Corrosion and wear resistance, suitable for harsh environments: Stainless steel material itself has excellent corrosion resistance, which can resist workshop oil stains, dust, water stains, and can also withstand humid warehouse environments or slight chemical medium contact; The tabletop has high hardness, is wear-resistant and impact resistant, and is not easily scratched or deformed after long-term use, making it suitable for high-frequency work scenarios.

3. Easy to clean and maintain, in compliance with hygiene standards: The countertop is smooth without pores, and there are no hygiene blind spots. Oil stains, dust, and dirt can be directly wiped with a cloth, or rinsed with water or neutral cleaning agents, without the need for complex cleaning processes; The material is not prone to breeding bacteria and mold, and can meet food and pharmaceutical hygiene requirements in some scenarios, while also reducing the cleaning and management costs of warehouses and workshops.

4. Flexible adaptation and multifunctional combination: Sizes can be customized according to actual needs (length 1000-3000mm, width 500-800mm, height 750-900mm conventional, supporting non-standard customization); Optional accessories such as drawers, shelves, hanging boards, guardrails, power sockets, etc. can be installed to achieve functions such as material classification and storage, tool hanging, temporary power supply, etc; The bottom casters can move flexibly, while the foot pads are stable and slip resistant, suitable for different workstation switching needs.

5. Long service life and outstanding cost-effectiveness: Stainless steel material is resistant to oxidation and aging, with a normal service life of up to 8-15 years, far exceeding wooden and ordinary iron workbenches; There is no need for frequent maintenance and replacement in the later stage. Although the initial procurement cost is slightly higher, the long-term cost-effectiveness is higher.

3、 Highlight advantages (compared to wooden/ordinary iron workbenches)

-Compared to wooden workbenches: it solves the pain points of moisture, mold, deformation, and insect infestation of wooden countertops, especially suitable for damp environments in warehouses; Wear resistant, impact resistant, and will not be damaged due to heavy object placement or collision; Easy to clean, no need to worry about oil infiltration, better hygiene.

-Compared to ordinary iron workbenches: it avoids the problems of easy rusting and poor corrosion resistance of iron workbenches, and does not require frequent painting maintenance; The surface is smoother and will not contaminate materials or products with impurities due to rusting; Widely applicable and suitable for production workshop scenarios with slight corrosion.

-Core competitiveness: It combines "stability+corrosion resistance+hygiene+flexibility", can adapt to the diverse needs of production workshops and warehouses, and has low maintenance costs and long service life. It is a "strong universality and high durability" basic equipment for industrial scenarios.

4、 Applicable scenarios

1. Core applications in the production workshop

-Mechanical processing workshop: used for component assembly, semi-finished product testing, tool storage, and temporary operations. It can resist oil stains and metal debris erosion, and the tabletop is wear-resistant and easy to clean.

-Electronic production workshop: Suitable for component sorting, circuit board assembly, product testing, stainless steel material does not generate static electricity (can be customized with anti-static models), good hygiene, and avoids dust and impurities contaminating electronic components.

-Food/pharmaceutical auxiliary workshop: used for material temporary storage and packaging auxiliary operations. Made of 304/316 stainless steel material that meets hygiene standards, it is easy to clean, not prone to bacterial growth, and can resist water stains and cleaning agent erosion during the cleaning and disinfection process.

-Automotive parts workshop: It carries the assembly and testing of heavy components, has strong stability, can adapt to high-frequency operations, is resistant to oil stains and impacts.

2. Core applications of the warehouse

-Goods sorting area: As a sorting operation platform, the table is spacious and flat, and can accommodate sorting tools, labels, and material boxes. It is easy to clean and suitable for warehouse dust environments.

-Temporary storage area for goods: used for temporarily storing heavy goods, fragile items or high-value materials, with strong load-bearing capacity, can be equipped with guardrails to prevent goods from falling off, and stainless steel material to resist the humid environment of the warehouse and prevent goods from getting damp.

-Warehouse maintenance area: As a maintenance workbench, it places maintenance tools and accessories, which can adapt to daily equipment maintenance, material packaging repair and other operations in the warehouse. It is wear-resistant and easy to maintain.

-Logistics packaging area: used for packing goods and attaching labels. The tabletop can withstand the pressure of the packing machine and heavy objects, and the smooth surface is easy for the packing belt to slide and clean.

Share