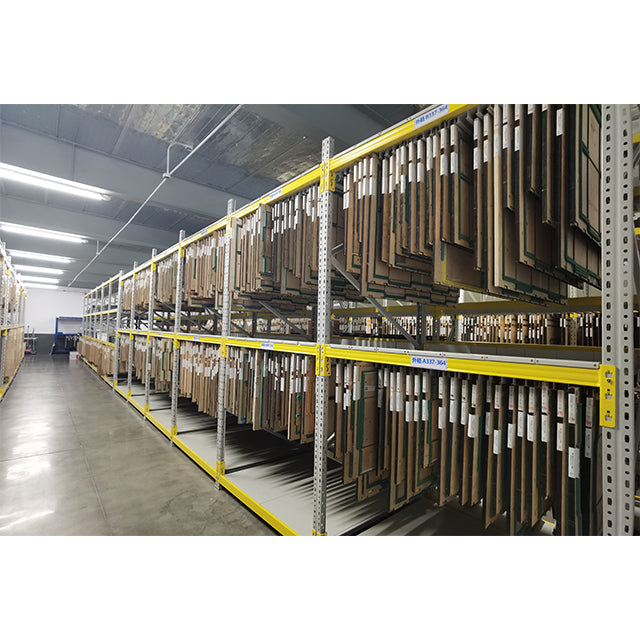

Knife frame

Knife frame

Analysis of the prominent advantages of knife frame frame

As a specialized equipment for storing knife molds in industries such as printing and packaging, the core value of knife mold frames lies in solving the problems of precision protection, efficiency improvement, and safety assurance in knife mold storage through scientific design. The following are their main advantages:

Precise protection of knife mold accuracy

The cutting edge and forming accuracy of the die directly affect the cutting quality of the product. The die frame achieves comprehensive protection through customized structural design

Wrap the storage area with soft rubber pads or EVA buffer layers to avoid direct contact between the cutting edge and the metal frame, which may cause chipping or curling;

Drawer style or slot style design combined with buckle fixing device can firmly lock the knife mold, preventing deformation caused by shaking during transportation or earthquakes;

Some high-end knife frames are equipped with dust covers and moisture-proof coatings, which can reduce the impact of dust adhesion and humidity on the corrosion of knife mold steel, especially suitable for long-term storage of high-precision tools such as precision electronic knife molds and laser knife molds.

Improve access and management efficiency

The knife frame greatly reduces management costs through systematic classification and storage:

Multi level slots can be designed according to the size of the cutting die (such as length and thickness), combined with colored label columns and number indexes. Operators can locate the target cutting die within 30 seconds, saving 80% of search time compared to disorderly stacking;

The rotating knife frame adopts a 360 ° turntable structure, combined with a sliding rail design, allowing a single person to access knife molds from different angles in a fixed position, reducing back and forth movement;

The intelligent knife mold frame integrated with the ERP system can automatically record the retrieval and return time by scanning the code, achieving digital tracking of the knife mold lifecycle and avoiding loss or duplicate purchases.

Save space and ensure safety

In terms of space utilization and operational safety, the knife frame has significant advantages:

The vertical knife frame utilizes vertical space, saving more than 60% of ground space compared to flat stacking with the same storage capacity, especially suitable for small and medium-sized workshops;

In terms of load-bearing capacity, the high-quality knife frame is welded with Q235 steel, with a single slot load-bearing capacity of 50-100kg. Combined with a reinforced base and anti slip foot pad, it can withstand slight collisions during forklift operations;

Anti tipping design (such as wall fasteners, widened footings) and safety locks can prevent personnel injury caused by accidental sliding of the knife mold, in compliance with OSHA safety standards.

Summary: The core value of knife frame frames

The advantages of the knife mold frame can be summarized as "one protection, two improvements, and three provinces" - protecting the accuracy of the knife mold, extending its service life, improving storage and management efficiency, saving space and safety costs. For enterprises that use dozens of knife molds daily, equipping appropriate knife mold frames can directly reduce the knife mold loss rate by 30% and shorten the preparation time for mold replacement from 1 hour to 15 minutes, which is a key equipment for cost reduction and efficiency improvement.

Share