Hot selling shelves fluent shelves

Hot selling shelves fluent shelves

The load-bearing capacity of fluent shelves needs to be comprehensively judged based on their structural design, component specifications, and application scenarios. It can usually be divided into three dimensions: single slide load-bearing, single-layer load-bearing, and overall shelf load-bearing. The specific scope and influencing factors are as follows:

1、 Range of core load-bearing parameters

Single slide bearing capacity

The load-bearing capacity of a single smooth/roller slide is a basic indicator, mainly depending on the material (metal/plastic), thickness, spacing, and installation method of the roller track. The common range is:

Lightweight slide: suitable for small items such as 3C accessories and cosmetics, with a single slide bearing capacity of 50-200kg;

Medium sized slide: suitable for small and medium-sized boxed goods (such as food and daily necessities), with a single slide bearing capacity of 200-500kg;

Heavy duty slide (specially customized): suitable for heavier components or fixtures, with a single slide bearing capacity of 500~1000kg (requires matching with thickened steel and reinforced support).

Single layer shelf load-bearing capacity

The total load-bearing capacity of a single-layer shelf is determined by the number of parallel slides on that layer, for example:

Lightweight shelves are equipped with 5 sliding tracks on a single layer, with a total load-bearing capacity of approximately 250-1000kg;

Medium sized shelves are equipped with 3-4 sliding tracks in a single layer, with a total load-bearing capacity of approximately 600-2000kg.

Overall shelf load-bearing capacity

The load-bearing capacity of the overall shelf is affected by the specifications of the columns, the strength of the crossbeams, and the floor height. The overall load-bearing capacity of conventional medium-sized fluent shelves is mostly between 5000-10000kg, while heavy-duty customized ones can be higher, but stability needs to be ensured through structural mechanics calculations.

2、 Key factors affecting load-bearing capacity

Material and Craftsmanship

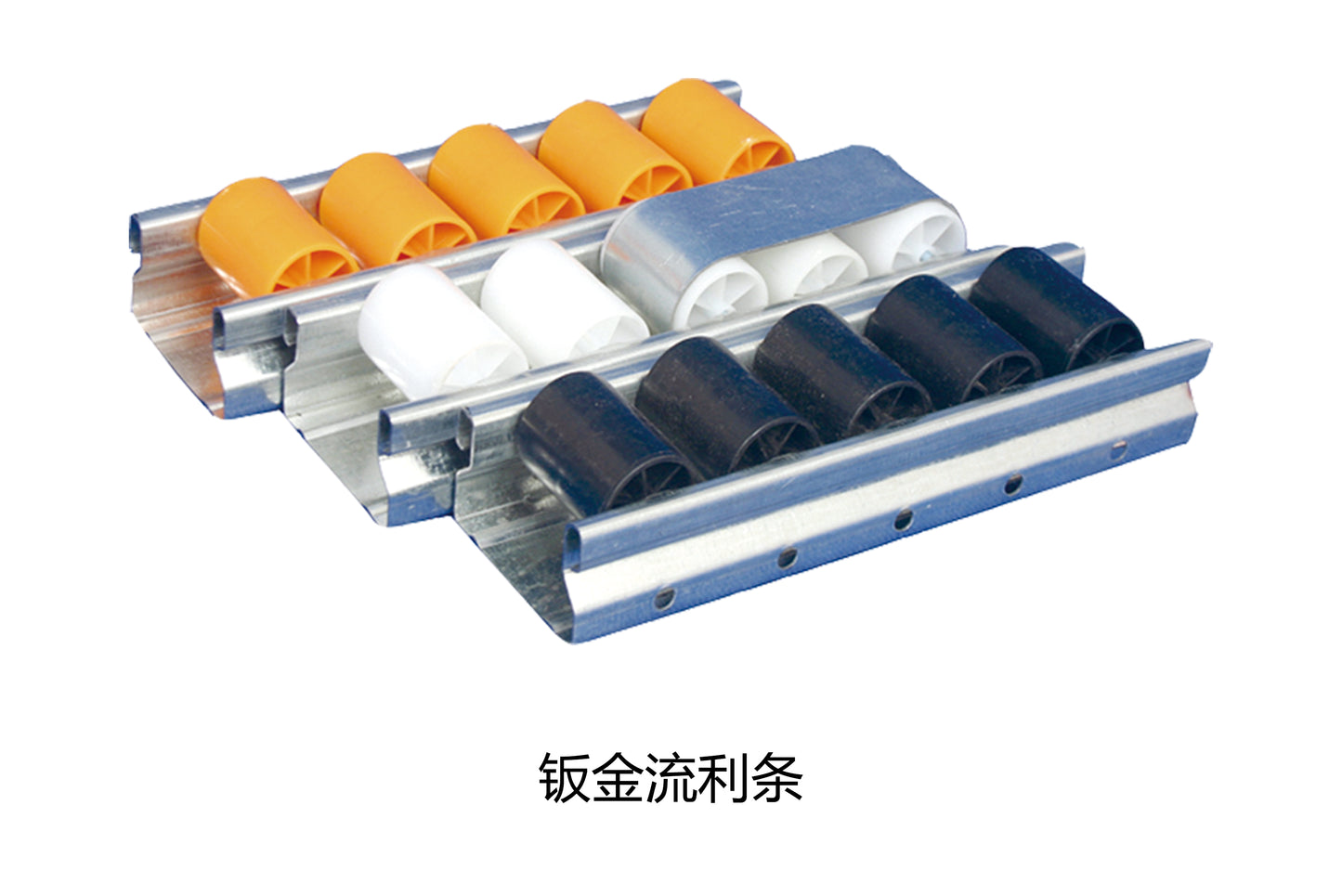

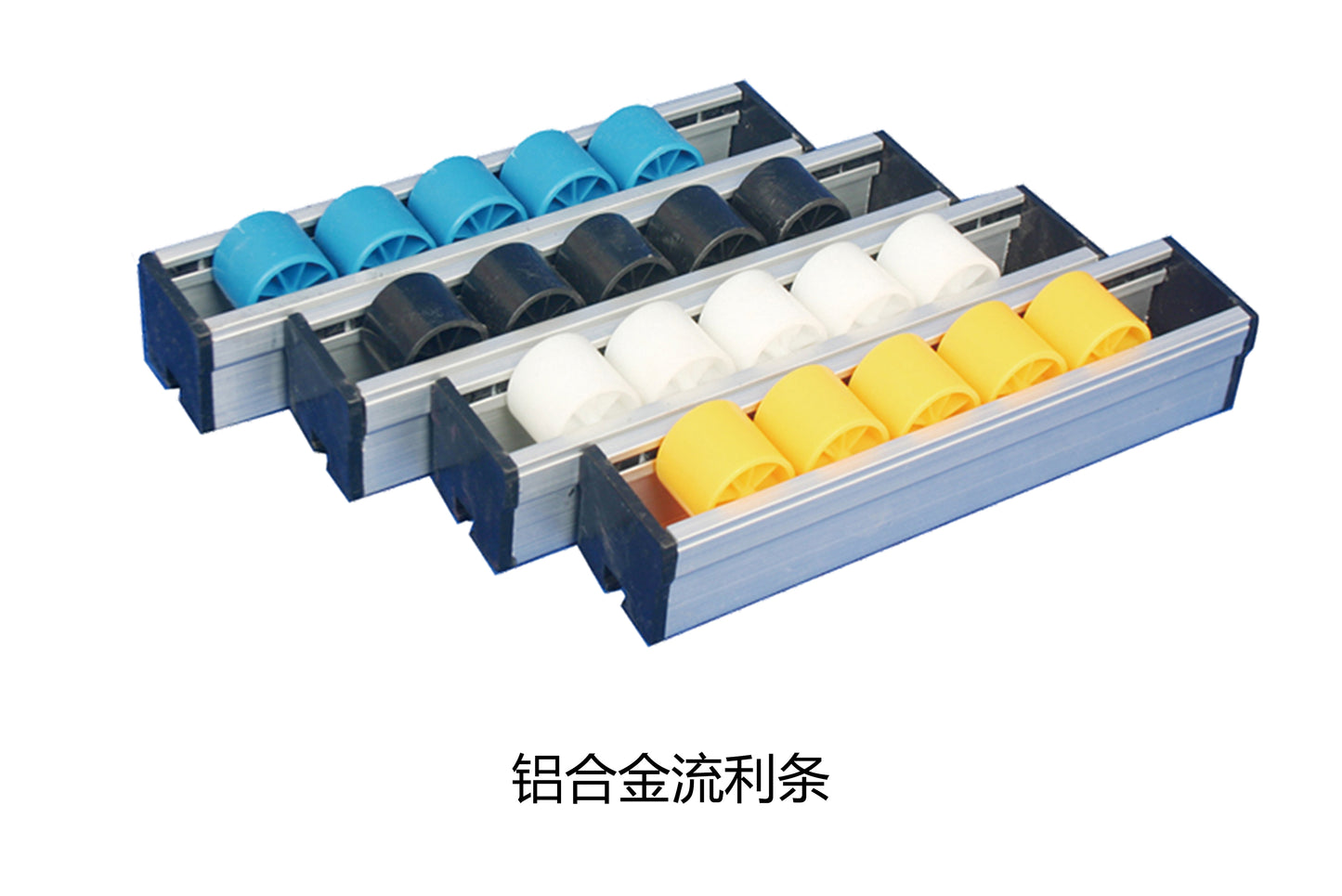

Fluent strip: Metal fluent strips (galvanized steel, stainless steel) have a much higher load-bearing capacity than plastic fluent strips, and the thicker the thickness (such as 2.0mm vs 1.2mm), the stronger the load-bearing capacity;

Beam and Column: Columns and beams made of Q235 or higher strength steel, combined with welding/bolt fastening processes, can increase the overall load-bearing limit.

structural design

Track spacing: The smaller the spacing between tracks (i.e., the denser the support points), the more uniform the load on the goods, and the more stable the load-bearing capacity;

Tilt angle: If the angle is too steep (>15 °), it may cause the goods to slide too quickly and increase the impact load. It is usually recommended to control the tilt angle between 3 ° and 8 ° (adjusted according to the weight and friction coefficient of the goods);

Support method: If the fixed brackets at both ends of the slide are reinforced with triangular supports or welded, they can better distribute the load than ordinary buckle type.

cargo characteristics

Weight distribution of goods: If the center of gravity of the goods is offset or a single point is subjected to excessive force (such as irregularly shaped goods), the actual load-bearing capacity needs to be reduced by 20% to 30%;

Unit size: Goods that match the length and width of the slide (gap ≤ 5cm) can avoid jamming or uneven force during sliding, ensuring load-bearing stability.

3、 Precautions for Load bearing Design

Safety redundancy: In practical applications, 10% to 20% of load-bearing redundancy should be reserved to avoid component fatigue caused by long-term full load use;

Customization requirements: For overweight goods (such as automotive parts and heavy fixtures), it is necessary to communicate with the manufacturer in advance and customize them through methods such as thickening steel, strengthening support, optimizing structure, etc;

Regular testing: After long-term use, it is necessary to check for issues such as wear and tear of the flow bar, deformation of the crossbeam, and loose connections, and maintain them in a timely manner to ensure load-bearing safety.

summarize

The load-bearing capacity of fluent shelves mainly covers light to medium sizes, and can meet the storage needs of small and medium-sized goods (single slide ≤ 500kg) in conventional scenarios. Special customized models can be adapted to heavy-duty scenarios. When selecting, it is necessary to consider the weight, size, and turnover frequency of the goods, and the manufacturer should provide a load-bearing plan through structural calculations to ensure a balance between safety and efficiency.

Share