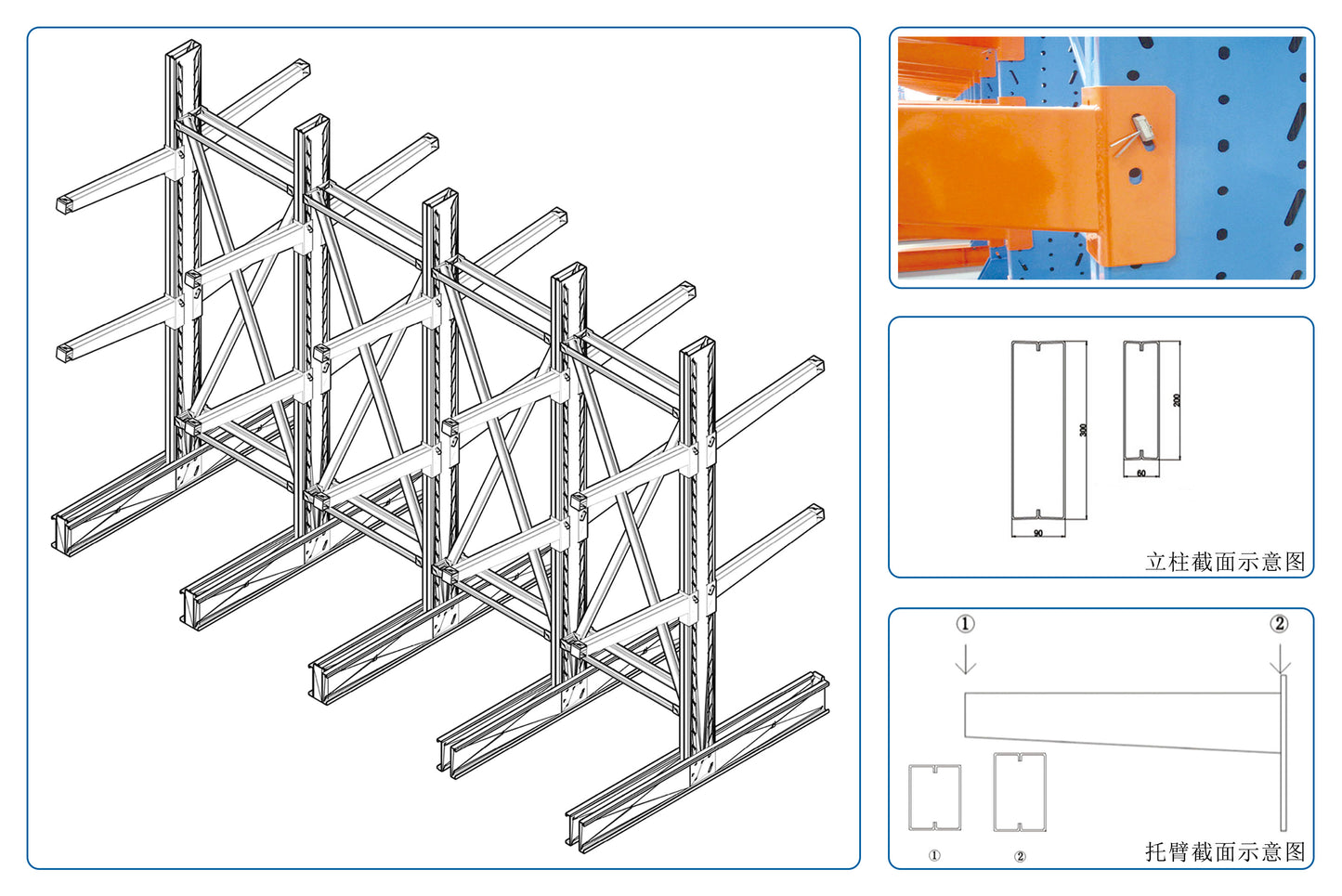

Cantilever Racking

Cantilever Racking

Ensuring the safety and stability of cantilever shelves is the core goal in the selection and use process, which requires multidimensional system control from structural design, material selection, connection strength, safety accessories, installation specifications, and daily maintenance. The following are specific key measures and precautions:

1、 Controlling safety from the source of structural design: the core guarantee of load-bearing and stability

Structural design is the foundation of shelf safety, which needs to meet mechanical stability and load-bearing requirements to avoid deformation or collapse caused by design defects.

Accurately matching load-bearing requirements and eliminating overload design

Clarify the load-bearing capacity of a single cantilever and the overall shelf: Based on the weight of the goods and the number of piles, calculate the actual force on a single cantilever (including the weight of the goods and the dynamic impact force during storage and retrieval), ensuring that the design load-bearing capacity is ≥ 1.2 times the actual demand (with a 20% safety margin reserved).

Reject the "one size fits all" design: Heavy goods (such as ≥ 1500kg/cantilever) need to undergo separate structural mechanics calculations, with a focus on verifying the stress distribution at the connection points between the cantilever and the column, as well as at the bottom of the column, to avoid excessive local stress leading to fracture.

Require suppliers to provide load-bearing test reports and mechanical calculations (in accordance with GB/T 28576-2012 "Design Specification for Storage Shelves") to ensure design compliance.

Optimize structural anti roll and rigidity design

Slant support must be added for high shelves: for shelves with a height of ≥ 4m, diagonal braces (spacing ≤ 2m) shall be added along the height direction at the back of the column to form a triangle stable structure and enhance the ability to resist lateral forces (such as forklift collision and cargo eccentric load).

Double sided cantilever with horizontal tie rod: Double sided cantilever shelves (without wall support in the middle) require the installation of horizontal tie rods at the top and middle of the columns to connect adjacent columns, enhance the rigidity of the overall frame, and avoid column tilting when subjected to unilateral force.

Control the length and spacing of the cantilever: The cantilever length should not be too long (usually ≤ 3m, heavy-duty shelves ≤ 2.5m), as being too long can easily cause the cantilever to sag and deform; The spacing between adjacent cantilevers should be uniform and match the width of the goods (spacing>cargo width 5-10cm), to avoid overloading and compression of the goods.

2、 Strict selection of materials and connection processes: the key to strength and durability

The material quality and connection strength directly determine the load-bearing capacity and service life of the shelf, and it is necessary to avoid the risk of cutting corners from the source.

Steel material and specifications meet the standards

Core load-bearing component material: Q235 low carbon steel (medium and light shelves) or Q345 low alloy steel (heavy shelves) should be selected for the main structure such as columns and cantilevers. These types of steel have high yield strength (Q235 ≥ 235MPa, Q345 ≥ 345MPa) and strong deformation resistance.

Reject non-standard steel: Require suppliers to provide steel material certificates (such as steel mill quality assurance certificates) to avoid using recycled steel and miscellaneous steel (which are prone to brittle fracture and lack strength).

Thickness standard: The thickness of the cantilever main arm is ≥ 5mm (light) and ≥ 8mm (heavy); Column thickness ≥ 3mm (light) and ≥ 5mm (heavy), insufficient thickness can easily lead to bending after long-term load-bearing.

The connection process must be firm and reliable

Connection between cantilever and column: Priority should be given to the composite method of "welding+bolt reinforcement" - the welding between the cantilever root and the column should be fully welded (weld height ≥ 0.8 times the thickness of the steel), without virtual welding or missed welding; Simultaneously, use high-strength bolts (grade 8.8 or above) for secondary fixation to prevent loosening after welding fatigue.

Connection between column and base: The base should be made of integral steel plate (thickness ≥ 8mm) and welded firmly to the column; The heavy-duty shelf base must be fixed to the concrete floor with M12 or above expansion bolts (concrete strength ≥ C20, thickness ≥ 150mm), with bolt burial depth ≥ 100mm, to ensure that the overall structure does not overturn.

Check the process details: rust removal treatment (such as grinding, spraying anti rust paint) should be carried out at the welding site to avoid later corrosion affecting the strength; Bolt connections require the addition of spring washers or anti loosening nuts to prevent vibration loosening.

3、 Configure necessary security attachments: reduce operational risks

Safety accessories are the "last line of defense" for shelf safety, which can effectively prevent hidden dangers such as cargo slipping and structural collisions.

Anti falling accessories for goods

Install a stopper at the end of the cantilever: All cantilever outer ends must be equipped with steel stoppers (height ≥ 50mm, thickness ≥ 8mm) or rubber anti-collision stoppers to prevent goods from slipping due to slight collisions or tilting.

Anti slip and isolation design: When storing cylindrical goods (such as steel pipes and coils), V-shaped rubber pads or patterned steel plates need to be added to the cantilever surface to increase friction; When stacking multiple layers, layered partitions (such as wooden/steel barriers) can be installed to prevent deformation caused by mutual compression of goods.

Anti structural collision protection

Column anti-collision foot protection: anti-collision foot protection (made of thick walled steel pipe or high-density rubber, with a height of ≥ 300mm) should be installed at the bottom of the channel side column to buffer the impact force of forklifts, ground oxen and other equipment, and protect the column from deformation.

Top limit sign: The top of the shelf should be posted with signs such as "maximum height limit" and "no climbing" to avoid collision with the top structure when accessing equipment (such as forklifts).

4、 Standardized installation and acceptance: ensuring construction quality

Even if the design is reasonable, improper installation can still lead to safety hazards, and installation standards must be strictly followed and accepted.

installation processing control

Ground pre-treatment: Before installation, ensure that the ground is flat (with a horizontal error of ≤ 5mm/m), without any depressions or protrusions, to avoid the shelves tilting due to uneven ground.

Column verticality calibration: The verticality error of a single column is ≤ 1mm/m, and the cumulative verticality error of the entire row of shelves is ≤ 10mm, to avoid uneven force caused by tilting.

Cantilever levelness inspection: The horizontal error of the cantilever on the same layer is ≤ 3mm, ensuring that the goods are stacked smoothly and not loaded unevenly.

Acceptance core indicators

Load bearing test: After installation, a full load test (loaded at 1.2 times the designed load capacity and left to stand for 24 hours) is required to check whether the cantilever is sagging (allowable sagging amount ≤ L/200, L is the length of the cantilever), whether the column is tilted, and whether the bolts are loose.

Comprehensive inspection: Check the welding quality one by one (without cracks or pores), bolt tightness (tested with a torque wrench to meet the design torque), and integrity of safety accessories to ensure no hidden dangers are missed.

5、 Daily maintenance and regular inspections: extending safety life

The safety of shelves requires long-term maintenance, and an inspection mechanism should be established in daily use to promptly detect and repair problems.

Regular inspection content (recommended once a month)

Structural deformation: Check whether the cantilever is bent or sagging (if it exceeds L/200, it needs to be stopped for maintenance), whether the column is tilted, and whether the weld seam is cracked.

Loose connection: Use a wrench to check all bolts (especially the bolts between the cantilever and the column, and between the base and the ground) to ensure that they are not loose; If rust or cracks appear at the welding point, timely rust removal, welding repair, and painting are required.

Accessories intact: Check if the stopper, anti-collision foot guard, and anti slip pad are damaged or detached, and replace them in a timely manner.

Standardized usage requirements

Overloading is strictly prohibited: "Maximum Load Capacity Mark" (such as "Single Cantilever Load Limit 1000kg") should be prominently posted on the shelves, and it is strictly prohibited to stack goods with a weight exceeding the design value.

Avoid rough handling: When using forklifts or cranes to access goods, slowly approach the shelves and maintain a distance of ≥ 30cm from the cantilever. Do not collide or drag the goods.

Environmental protection: In humid environments (such as outdoors and workshops), it is necessary to regularly spray anti rust paint on the shelves; Scenarios with high levels of dust need to be cleaned regularly to avoid dust accumulation and accelerated corrosion.

Summary: The core logic of security and stability assurance

The safety and stability of cantilever shelves need to be integrated throughout the entire process of "design materials process accessories installation maintenance": the design meets the requirements of load-bearing and anti roll, materials and processes ensure strength, accessories prevent risks, and installation and maintenance ensure long-term reliability. When selecting, priority should be given to examining the supplier's design qualifications (such as whether they have professional structural engineers), case experience (similar industry application cases), and after-sales service (whether they provide regular maintenance guidance), in order to reduce safety hazards from the source.

Share