Cantilever Racking

Cantilever Racking

Choosing a suitable cantilever rack requires comprehensive consideration of multiple dimensions such as cargo characteristics, storage requirements, space conditions, and safety regulations to ensure that the rack can meet practical usage needs while ensuring storage efficiency and operational safety. The following are the specific selection steps and key considerations:

1、 Clarify the core parameters of goods: the foundation of shelf design

The characteristics of the goods are the primary basis for selecting cantilevered shelves, and the following information needs to be accurately calculated:

Type and form of goods

Clarify whether the goods are in the form of long strips (such as steel pipes, wood), heavy parts (such as molds, metal bars), irregular parts (such as cable reels, glass profiles), or whether there is vulnerability (such as glass, precision pipes).

If the goods are cylindrical (such as steel pipes, coils), it is necessary to consider whether to install V-shaped support arms or anti slip pads to avoid rolling; If it is a sheet material, it needs to be confirmed whether layered isolation is required.

Cargo size parameters

Length: The length of a single piece of goods determines the length of the cantilever (the cantilever length should be slightly longer than the length of the goods, usually leaving 10-20cm of operating space to avoid deformation of the cantilever due to prolonged hanging of the goods).

Width/diameter: affects the spacing between cantilevers (the spacing between adjacent cantilevers should be slightly larger than the width/diameter of the goods to ensure smooth access).

Height: determines the height of the shelf (the height of the shelf should be greater than the height of the goods+the clearance for access operations, usually reserved by 30-50cm).

Cargo weight parameters

The weight of a single unit/item of goods directly determines the load-bearing capacity of a single cantilever (it is necessary to clarify the "single cantilever load-bearing", rather than the overall shelf load-bearing).

Total load capacity per layer: The total weight of goods stacked on each layer of a single row cantilever should be ≤ the layer load capacity of the shelf design (determined by the strength of the column and cantilever connection).

Attention: A 10% -20% margin should be left for load-bearing capacity to avoid structural fatigue caused by long-term full load.

2、 Determining load-bearing capacity and structural strength: the core guarantee of safety

The load-bearing capacity of cantilever shelves is determined by steel specifications and structural design, and special attention should be paid to:

Cantilever bearing grade

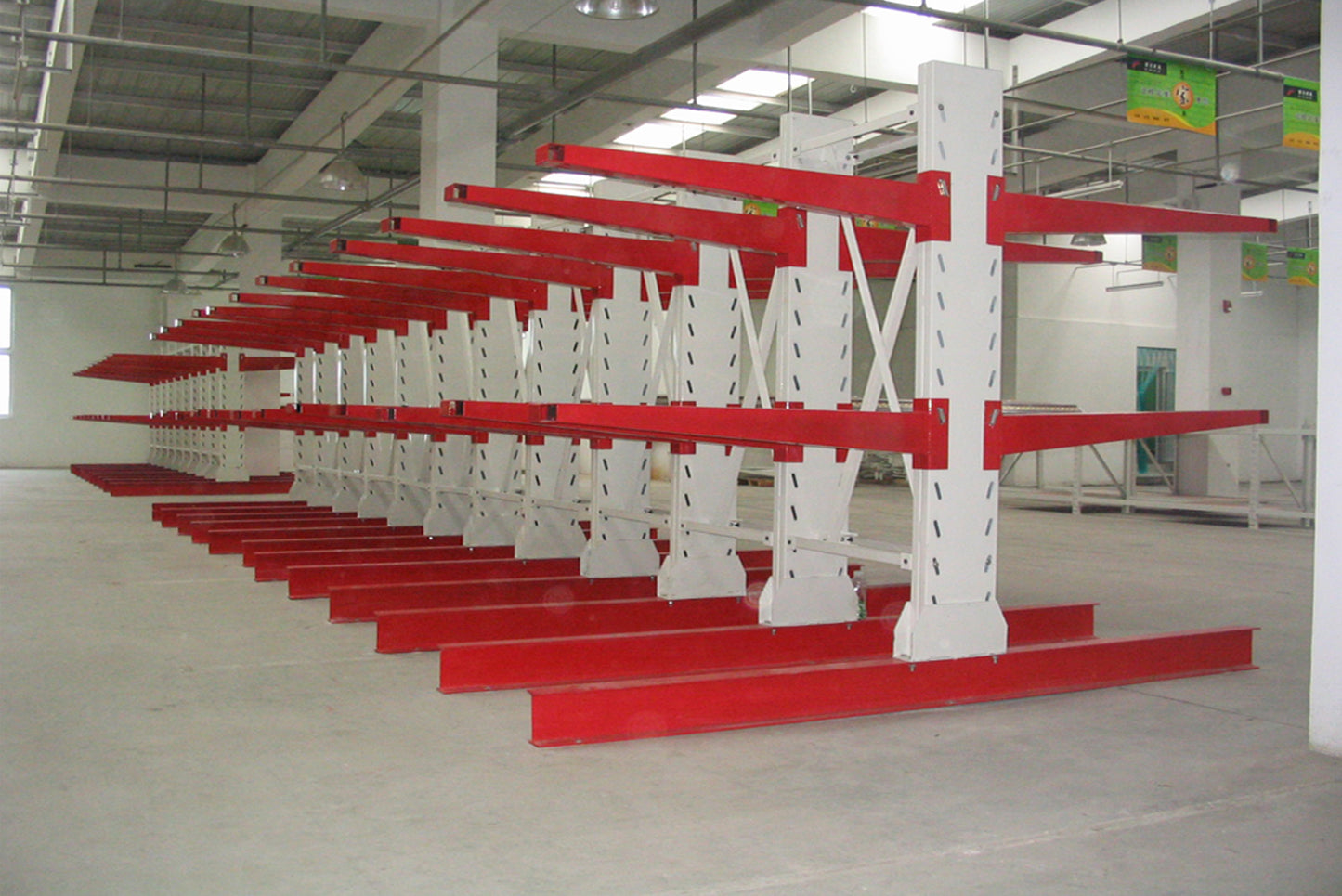

According to the single cantilever load-bearing capacity, it is divided into light (≤ 500kg), medium (500-1500kg), and heavy (≥ 1500kg). Lightweight suitable for pipes, wood, etc; Heavy duty is suitable for molds, large steel components, etc.

The load-bearing capacity should match the thickness of the steel: the thickness of the cantilever main arm is usually ≥ 5mm, and the thickness of heavy-duty shelves should be ≥ 8mm; the thickness of the column should be ≥ 3mm, and the thickness of heavy-duty shelves should be ≥ 5mm.

Structural stability design

The connection method between cantilever and column: welding+bolt reinforcement is preferred (welding ensures strength, bolts are easy to maintain), avoiding relying solely on bolt connection (long-term load-bearing is prone to loosening).

Fixed at the bottom of the column: Heavy duty shelves need to be fixed to the ground with expansion bolts (concrete strength ≥ C20) to prevent tipping; Lightweight and can be fixed as needed.

Slant support reinforcement: slant support shall be added at the back of the column for high shelves (≥ 4m) to enhance the anti roll ability (especially when working with forklifts).

3、 Matching storage space and access methods: the key to improving efficiency

Warehouse space adaptation

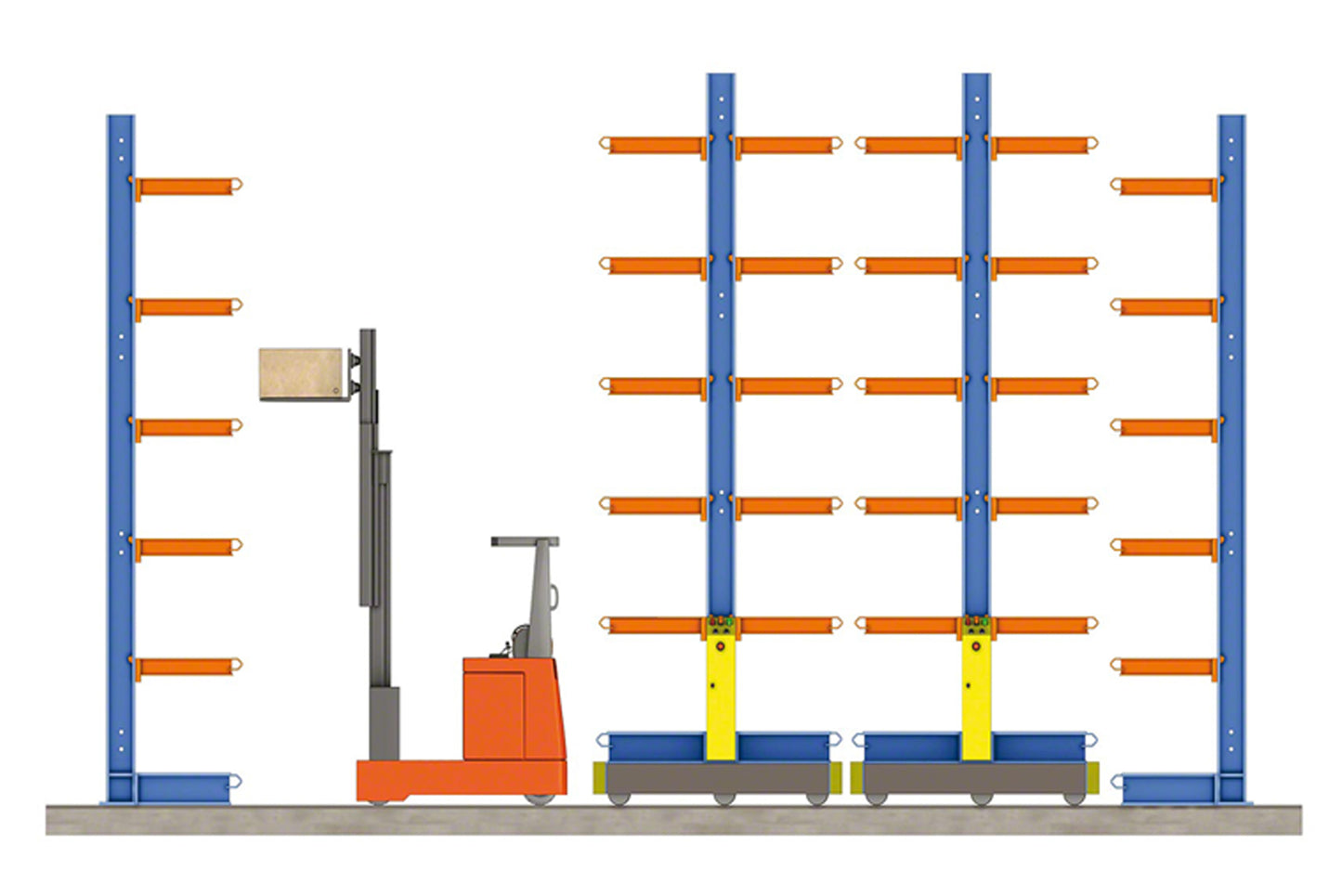

Warehouse height: The total height of the shelves is ≤ the available height of the warehouse - the height of the lighting/fire-fighting facilities - the height of the access equipment operation (such as reserving 1-2m for forklift lifting).

Channel width: determined according to the type of access equipment (forklift channel must be ≥ 2.5m, crane channel must be ≥ 3m), to avoid operation obstruction caused by narrow channels.

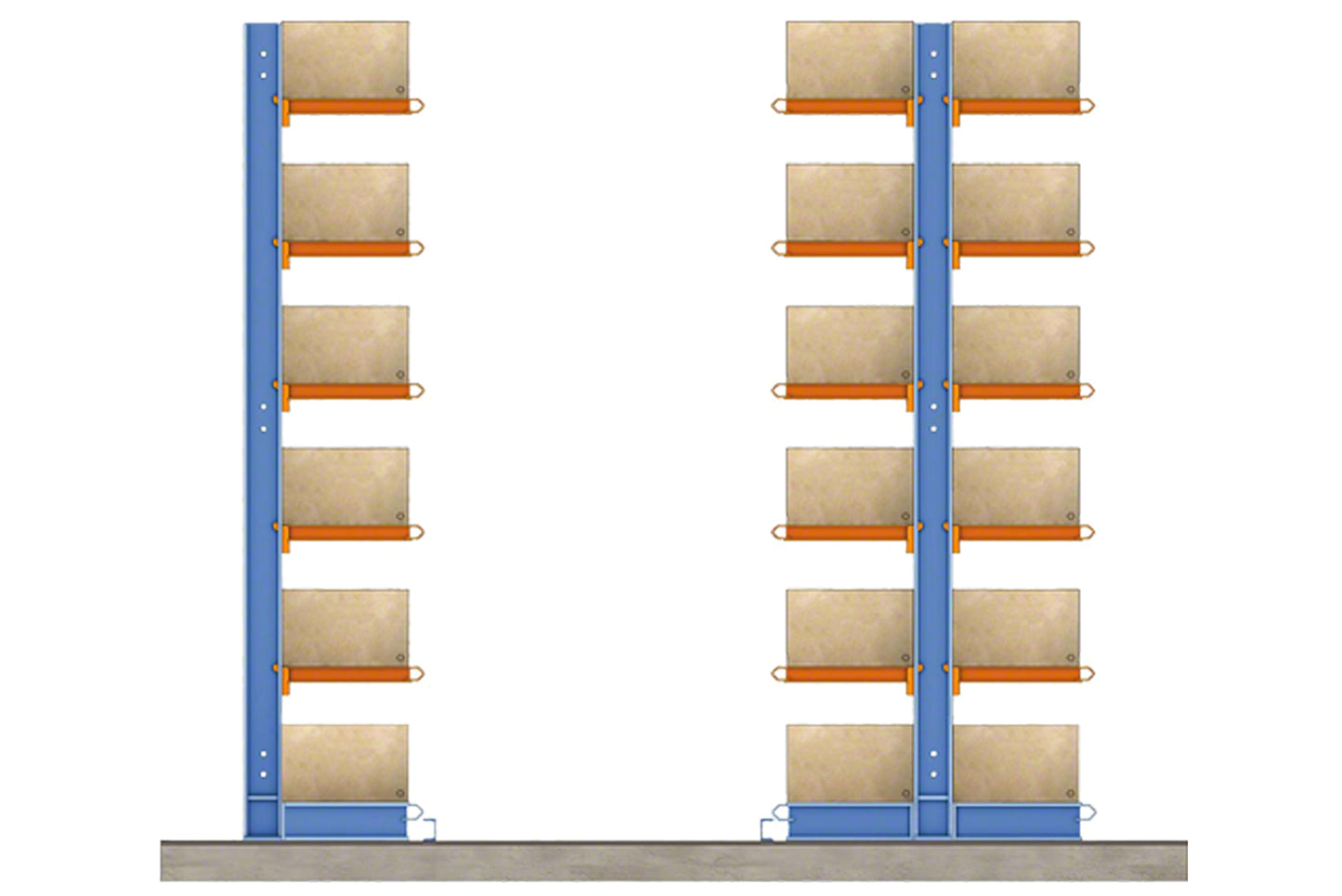

Single/double-sided cantilever selection: Use single-sided cantilever in the wall area (to save space), and double-sided cantilever in the middle area (for higher utilization).

Compatibility of access devices

If using a forklift for access: the cantilever length should be ≤ the maximum extension of the forklift (usually the forklift is compatible with a cantilever length of ≤ 2.5m), and the cantilever spacing should be ≥ the width of the forklift fork.

If using a crane/trolley: sufficient lifting space should be reserved, and the vertical distance between the top of the cantilever and the crane hook should be ≥ 0.5m to avoid collision.

If manually accessed: Lightweight shelves can reduce the floor height (≤ 2m) for easy handling.

4、 Choosing materials and processes: Ensuring durability

Steel material

The mainstream material is Q235 low-carbon steel (with high cost-effectiveness, suitable for medium and light-duty shelves); It is recommended to use Q345 low-alloy steel (with higher strength and stronger deformation resistance) for heavy-duty shelves.

To avoid using non-standard steel (such as recycled steel), suppliers are required to provide proof of steel material.

Surface treatment process

Indoor dry environment: Optional electrostatic spraying (low cost, beautiful, average anti-corrosion).

Wet/outdoor environment (such as outdoor storage of building materials): Hot dip galvanizing process must be selected (zinc layer thickness ≥ 80 μ m, strong corrosion resistance, and a service life of more than 10 years).

Check the process details: There should be no missed or virtual welding at the welding point, and the surface coating should be uniform without bubbles.

5、 Pay attention to safety and compliance: avoid operational risks

Security Attachment Configuration

Fall prevention device: High rise shelves need to be equipped with blocking blocks or guardrails at the cantilever ends to prevent goods from slipping.

Anti slip design: Rubber pads or patterned steel plates can be added to the cantilever surface to increase friction (especially when storing cylindrical goods).

Column protection: Anti collision foot guards (thick walled steel pipes or rubber materials) should be installed on the side columns of the channel to prevent deformation caused by forklift collisions.

Compliance requirements

It is required to comply with the national standard "Design Specification for Storage Shelves" (GB/T 28576-2012), and the supplier is required to provide structural mechanics calculations and load-bearing test reports.

If used for storing hazardous materials (such as heavy metal parts, flammable pipes), additional industry safety regulations (such as fire prevention and anti-static) must be met.

Share